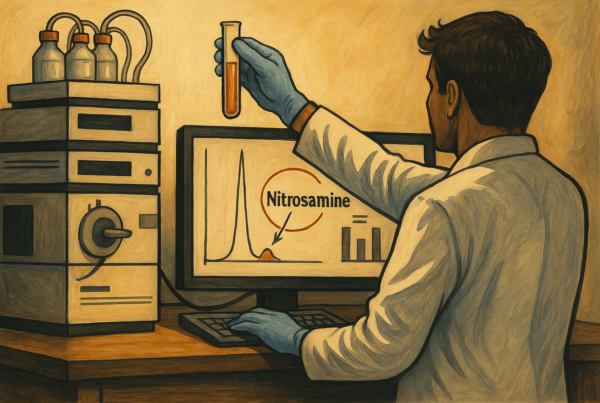

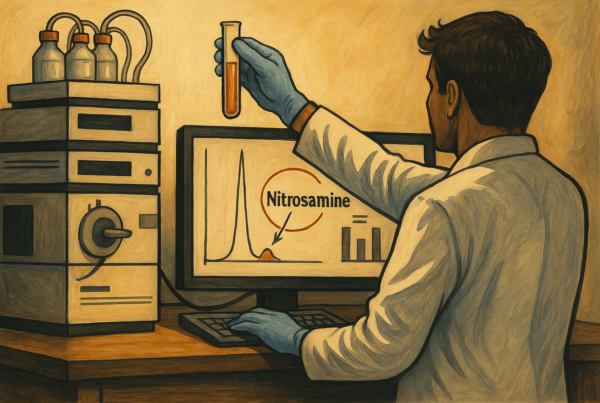

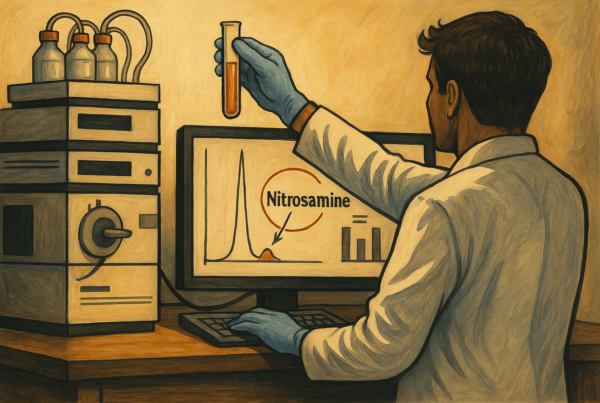

Introduction Nitrosamines have been identified as potential impurities in pharmaceuticals, raising significant concerns due to their carcinogenic properties. Regulatory agencies, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have intensified scrutiny on nitrosamine contamination in drug products, prompting manufacturers to implement risk assessment and mitigation strategies. Sources of Nitrosamines in Pharmaceuticals Nitrosamines can form through various pathways, often as unintended byproducts of chemical synthesis, degradation, or interactions between raw materials. One common source is the reaction between secondary or tertiary amines with nitrosating agents (e.g., nitrites, nitrogen oxides) under mildly acidic or high-temperature conditions. APIs containing amine moieties or manufactured using amine-based reagents are particularly susceptible to forming Nitrosamine Drug Substance-Related Impurities, or NDSRIs. Additionally, contaminated solvents, catalysts, or excipients—such as lubricants or dyes—can introduce nitrosamine precursors into the production process. Cross-contamination from equipment or recycled materials may also contribute to the problem. After synthesis, nitrosamines can form during storage if drug products are…